7 ways to reduce pastry costs

This article aims to share 7 concrete tips for reducing costs in pastry making, with a particular focus on the stages of production : from equipment to ingredients, including purchasing and even plastic molds.

Here are strategies that will allow you to save on your production costs.

1. Choose ingredients, preferably local and especially seasonal

It's obvious, but favoring local and seasonal ingredients can significantly reduce purchasing costs while improving the freshness and taste of your pastries. Offering strawberries or cakes made from fresh raspberries in December is neither ecological nor economical, and above all the taste is not there for your customers.

Seasonal products are always cheaper when they are purchased at harvest time: you thus limit the impact on your cost price.

2. Buy in bulk

Negotiating wholesale rates or taking advantage of quantity purchase discounts for your ingredients and equipment can result in significant savings.

This requires carefully assessing:

- your needs over a given period

- DLUO for perishable products

- and finally the storage space you have available

3. Find cheaper alternatives

Test less expensive substitutes to replace some premium ingredients and reduce your costs. Be careful though, the objective is not to fall into the trap of "cheapflation*" by offering pastries made using artificial flavors or additives only.

However, you can, for example:

- Integrate Tonka bean, with a similar aroma, but much more powerful than vanilla or bitter almond: if its purchase price is comparable to that of vanilla, the quantity you will use to obtain a flavor comparable to vanilla is much lower.

- Working with vegetable butter made e.g. from a blend of shea, organic coconut and rapeseed oils. As a replacement for butter of animal origin, it is often less expensive to purchase and offers equivalent performance.

- Develop your own decorations : subjects, log ends and other decorations are obviously tempting but their increased unit cost impacts the final production cost of your cakes. To make them yourself, equip yourself with the appropriate molds, you will be able to keep them for a long time. Even though it takes time and ingredients to make these decorations, in the long run you will save money.

- Contact your suppliers or discuss good deals with your colleagues to source cheaper products or replace ingredients with less expensive equivalents.

* Cheapflation : this word is the contraction of the English term “cheap”, which means cheap/low-end, with the term inflation. The goal is to replace expensive ingredients with much cheaper substitutes such as additives, flavorings and fats. A method widely criticized by associations because it is misleading for consumers who pay the same price for a product that is ultimately less healthy.

4. Reduce waste

Put systems in place to minimize food waste. For example, reuse scraps of dough or use less aesthetic or advanced fruits to make secondary preparations (coulis, inserts, jellies or jams): this contributes to more economical management and above all avoids throwing away consumable foods.

5. Equip yourself second-hand

Investing in used pastry equipment in good condition is an effective way to reduce your production costs.

Pastry equipment purchased new represents a high cost and sometimes takes a long time to pay off. However, on the second-hand market, you can find inexpensive equipment that offers the same performance as new equipment.

Water jet cutting machines, chocolate temperers, freezers, mixers, ovens, dosers, straighteners, mixers, trolleys, all these essential equipment or those aimed at improving the productivity or comfort of pastry chefs represent costly investments in purchasing new, but more affordable second-hand. And improving productivity also means cutting costs!

You can also find the small equipment you need for everyday life on the second-hand market: nozzles, spatulas, stainless steel bowls, etc.

How to proceed ?

- Many websites offer this type of equipment: simply enter “ used XXX pastry machine ” into your search engine to find deals.

For example the purchase & sale site for professionals: https://alpagga.com/ . It offers second-hand equipment for CHR (Café, Hotel, Restaurant) and in particular for pastry making at prices of up to -50% of the new selling price: whipped cream machine, mixer, pastry tower, dresser, doser , etc. - Set up an alert on the Bon Coin website: you will receive an email as soon as a new advert is published with the targeted material.

- Also find out about sites that announce business failures (e.g. on repreneurs.com or announcements-liquidations.fr )

6. Reduce your energy consumption

Limit the use of air conditioning in the summer : use fans, or when your premises allow it, open the windows to create a circulation of fresh air rather than air conditioning your lab constantly.

Is air conditioning essential given your installation? Perhaps you can increase the set temperature by 1 or 2 degrees without compromising your production?

Replace energy-consuming lighting (neon lights, halogen lamps) with LED or low-consumption lamps.

Turn off unnecessary lights or when the premises are empty, and use natural light whenever possible.

7. Adapt your pastry offering

To save on costs, focus on simple recipes that require fewer ingredients and preparation steps .

A technically well-made dessert made from fresh products will be more profitable and economical than a sophisticated pastry made from premium ingredients and decorations purchased ready-made.

It's about finding an optimal balance to satisfy your customers by offering tempting pastries, while controlling production costs and the sales price of your desserts.

8th tip [BONUS] to reduce pastry costs

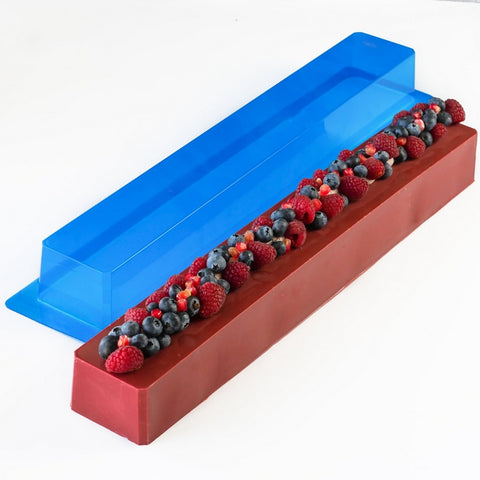

Plastic molds, an economical choice

One of the often overlooked but crucial aspects of reducing costs in baking concerns the choice of molds . Plastic molds, compared to silicone or metal molds , offer a clear economic advantage.

The cost of purchasing plastic molds is much cheaper than silicone or metal ones. With unit costs starting from €0.40 per dessert mold or €1 for a log mold , it is in fact much easier to equip yourself to launch mass production or to equip yourself with a wide range of dimensions : heights, diameters, lengths, you have the freedom to indulge yourself while saving money on your baking mold budget.

Other advantages of plastic molds:

- Limited storage space because the molds stack on top of each other, unlike stainless steel circles or log gutters

- Plastic molds prevent the formation of frost during freezing

- Consistent production quality : unmolding is always perfect and does not require rework

- No washing (in case you use them as disposable molds): energy savings, saving time for staff

- The cost allows you to equip yourself with a greater variety of molds without increasing the budget, to offer more formats in store

By integrating these molds into their daily practice, pastry chefs can not only achieve significant savings but also improve the efficiency of their production , two key elements for success and growth.

Reducing pastry costs is a constant challenge at all levels, from purchasing and choosing pastry creations to staff awareness. By adopting smart purchasing practices, minimizing waste, and choosing economical equipment, pastry businesses can significantly reduce their operational expenses. These savings can then be reinvested in areas that drive business growth, such as communication, purchasing new hardware, developing new products or improving the customer experience.

And you, what solutions have you adopted to reduce your production costs?